Laser marking

UFG srl offers laser marking or laser engraving on different types of materials, such as metals, oxidized aluminum, natural aluminum, glass, organic materials, fabrics, plastic materials in general, etc.

UFG offers its experience and latest generation machinery, fiber and CO2 laser marking technology that can satisfy every need.

Laser marking or engraving is effective for all types of objects, mechanical parts, furnishings, ships, etc.

Advantages

The advantages of laser marking or engraving are: precision and defined processing that does not damage the surfaces of the materials to be processed and speed of execution.

Fiber marking laser

Ideal for marking metals, plastics and painted materials. This technology allows precision, definition and speed in processing obtaining an extremely accurate result.

Fiber lasers is a solid-body laser that produces the laser beam by means of a so-called seed laser and amplifies it in specially-assembled glass fibers, to which energy is fed through pumping diodes. Thanks to their particularly small focal diameter, their intensity is up to 100 times higher than that of CO2 lasers with the same average power output.

They are suitable for these materials: metals, coated metals, plastics.

CO2 marking

CO2 marking lasers are gas lasers that use a gaseous mixture of electrically excited carbon dioxide. They are particularly suitable for processing non-metallic materials and most plastics. CO2 lasers have a high performance and excellent beam quality, that is why they are the most common type of laser.

They are suitable for these materials: plastic, glass, wood, acrylic, paper, fabrics, film.

Machining

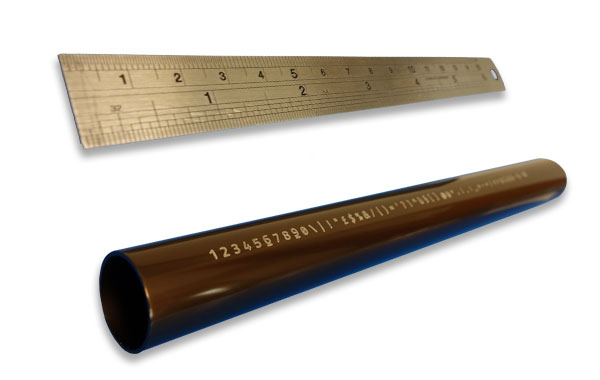

- Flat marking

- Marking in graduated scale on circumference

- Marking with graduated scale for slides

- Precision noni marking

- Generic workings

Italian

Italian English

English