How to choose the materials?

An essential step in the design process is the choice of material to use. In this page we can see how we can help Ashby maps for a quick and precise choice.

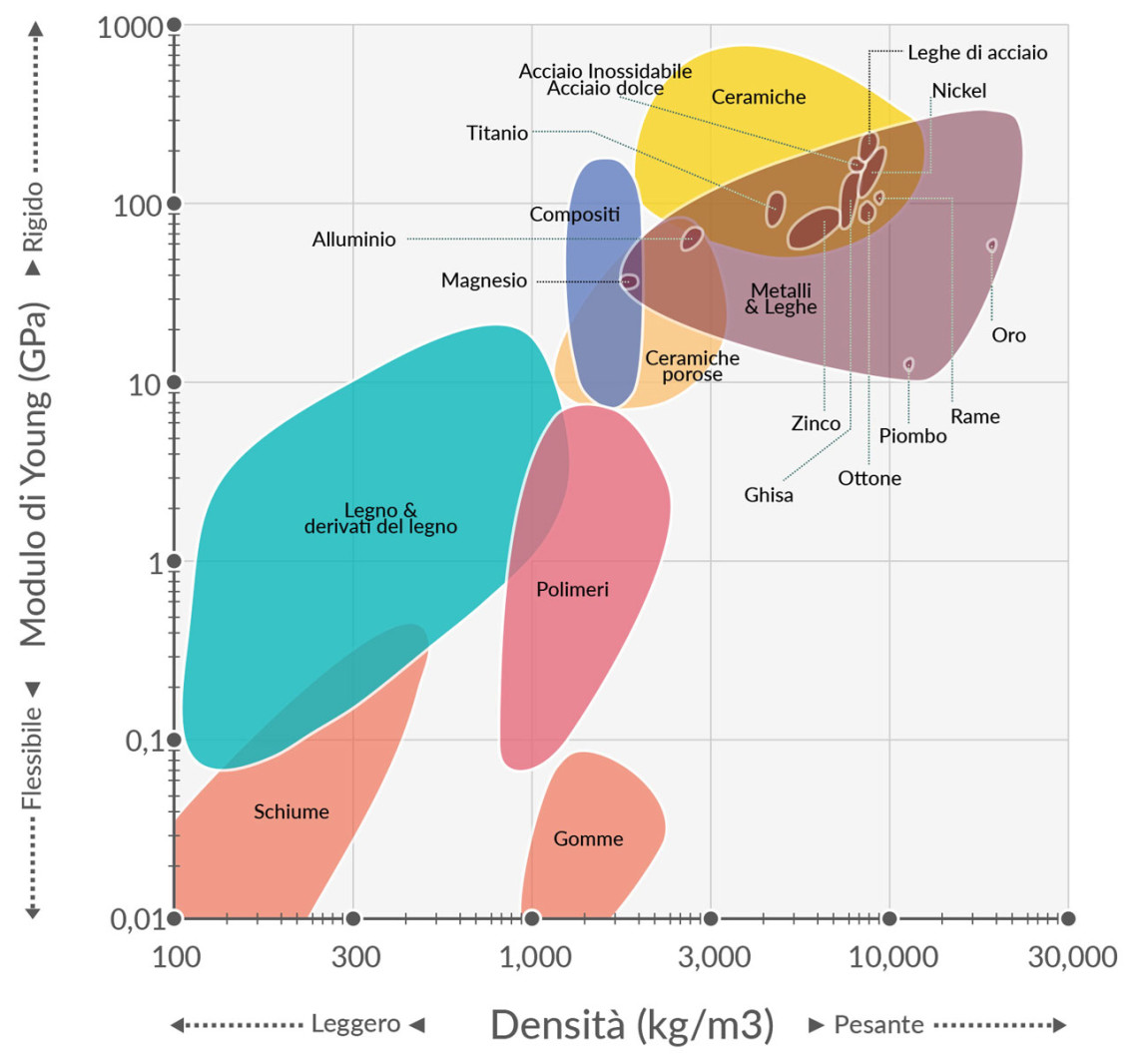

Density / Stiffness

The first map to consult is the one that allows us to understand which material is most suitable, understanding the need for lightness and rigidity of the product designed. In this map the model of young and density is related. From this table you can already understand which material may be most suitable for the design of the piece.

Conclusions on the choice of materials

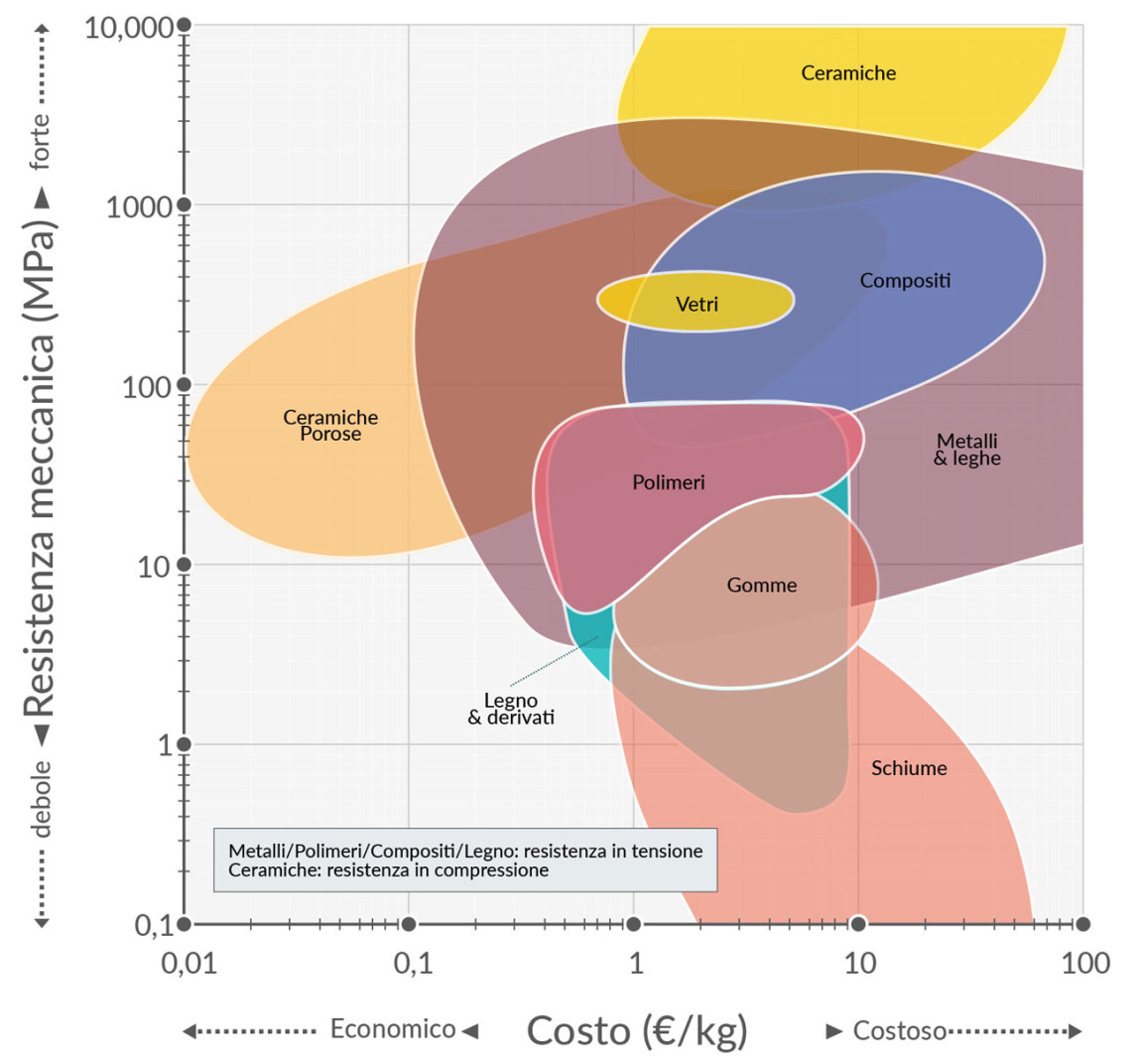

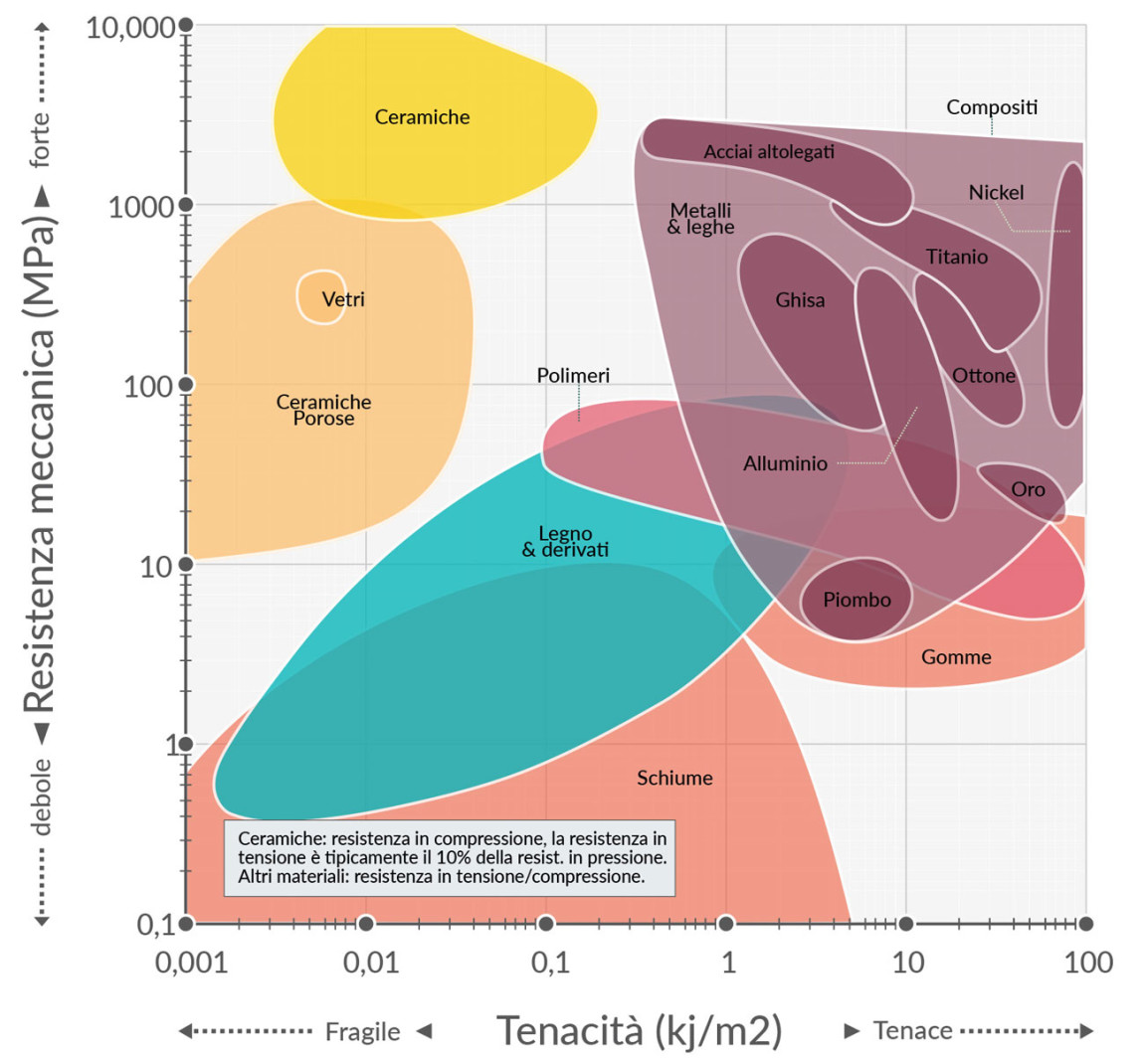

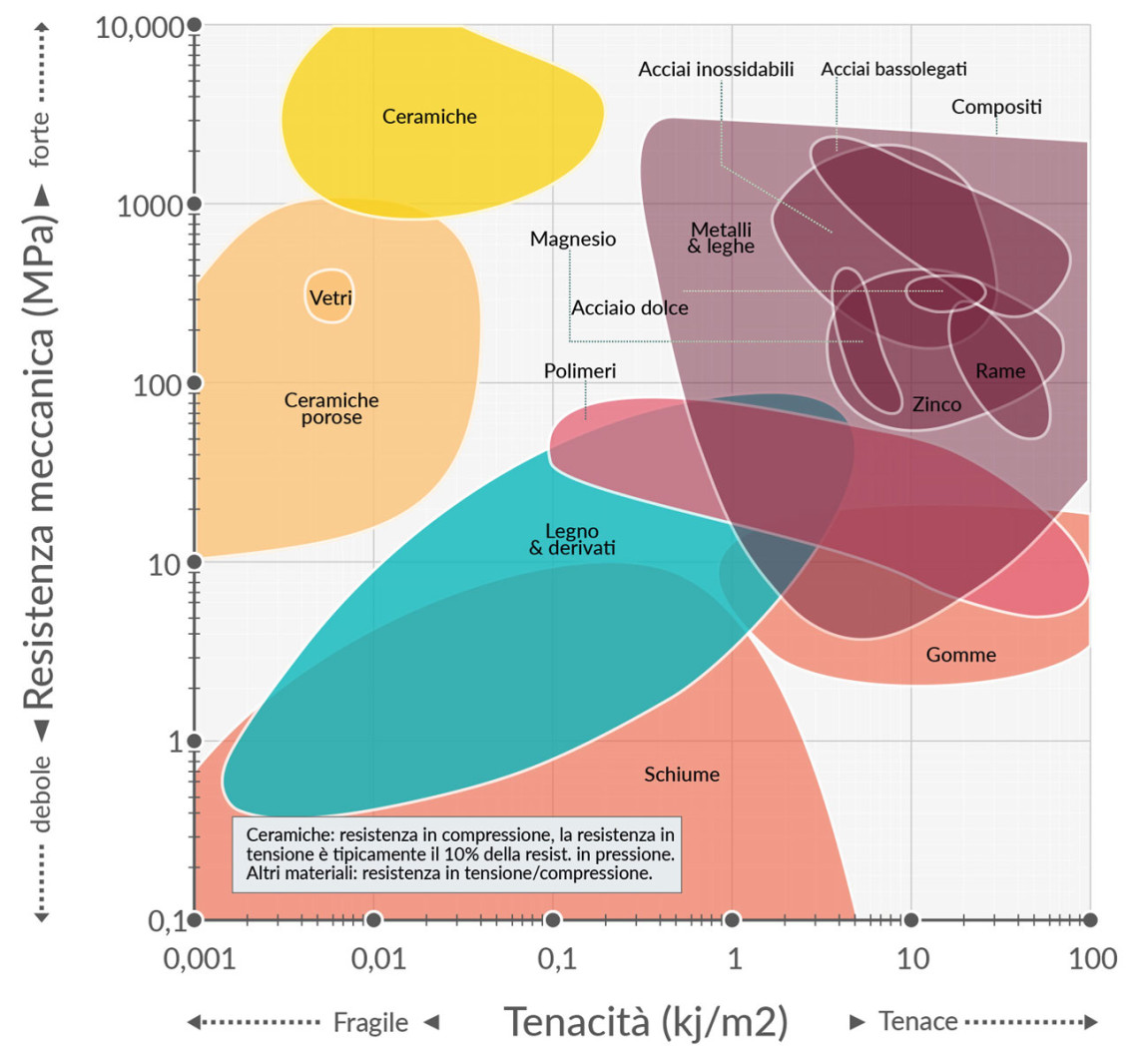

By comparing the various tables we are able to select together with our customers what is the best material for the realization of the project, respecting the timing and requirements of the project.

The various maps allow us to have a targeted choice and also to quickly identify alternatives on materials.

Italian

Italian English

English